The Weakest Metals: Exploring the Brittle Side of Materials

In the world of metals, strength and durability are highly valued characteristics. However, not all metals are created equal in terms of their resistance to deformation and fracture. Some metals are known for their weakness and brittleness, making them less suitable for certain applications. In this article, we will delve into the realm of the weakest metals and explore their properties, common uses, and limitations. By optimizing the use of the keyword "weakest metals," we aim to provide a comprehensive guide for those interested in understanding these materials.

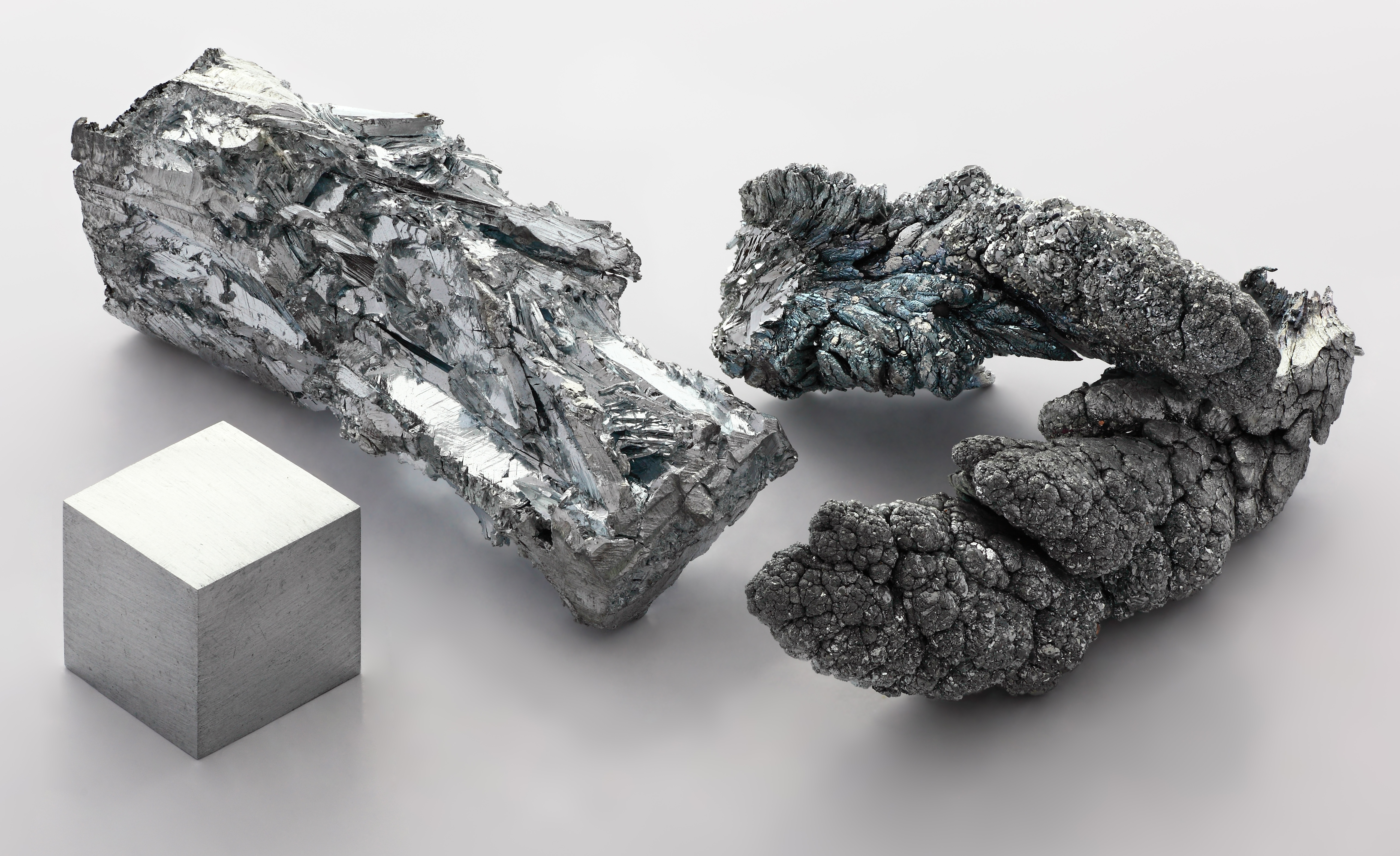

1. Aluminium

Aluminium

One of the commonly known weakest metals is aluminum. Despite its widespread use in various industries, aluminum exhibits relatively low tensile strength, making it prone to deformation and fracture. Its weak mechanical properties restrict its applications in structural components that require high strength, such as load-bearing beams or columns. However, aluminum's lightweight nature, corrosion resistance, and excellent thermal conductivity make it an ideal choice for industries like aerospace, packaging, and electrical conductors.

2. Zinc

Zinc

Zinc is another metal that falls into the category of weaker materials. Although it possesses good corrosion resistance, it lacks the necessary strength to withstand significant mechanical stresses. Zinc is commonly used as a protective coating for other metals, as it sacrificially corrodes to protect the underlying material. Additionally, it finds applications in the manufacturing of alloys, such as brass and bronze, where its weak mechanical properties are compensated by the addition of stronger metals.

3. Lead

Lead, known for its low melting point and high density, is also classified as a weak metal. Its malleability and ductility make it easy to shape, but its weak tensile strength limits its structural applications. Lead is commonly used in batteries, radiation shielding, and as a weight or ballast material. However, its toxicity has led to a decline in its usage over the years, as safety and environmental concerns have become more prominent.

4. Tin

Tin is a relatively weak metal that is often alloyed with other materials to enhance its mechanical properties. Its low tensile strength and brittle nature prevent its extensive use in load-bearing applications. Tin is predominantly utilized as a coating material for cans, providing corrosion resistance to steel. It is also used in soldering applications due to its low melting point and ability to form strong bonds between metal surfaces.

5. Bismuth

Bismuth, a brittle and weak metal, is widely recognized for its low tensile strength. However, it possesses unique properties, such as a low toxicity level and the ability to expand when solidifying, making it suitable for specific applications. Bismuth is used in pharmaceuticals, cosmetics, and as an alloying agent in the production of low-melting-point alloys. Its weak mechanical properties limit its use in load-bearing structures.

While strength is a crucial characteristic in the world of metals, the weakest metals discussed in this article have their own distinct properties and applications. Understanding the limitations of these materials is essential for selecting the appropriate metal for a given application. From aluminum's lightweight versatility to zinc's sacrificial corrosion protection, each weak metal serves a specific purpose in various industries. By optimizing the use of the keyword "weakest metals," this article provides valuable insights into the properties, uses, and limitations of these materials, aiding readers in making informed decisions when it comes to material selection.