Which Physical Method Can Separate a Mixture of Steel Ball Bearings and Marbles?

In various industrial and scientific processes, the need to separate mixtures arises frequently. One such scenario involves the separation of a mixture containing steel ball bearings and marbles. This article aims to explore different physical methods that can be utilized to achieve this separation effectively. By understanding these methods, professionals and enthusiasts alike can make informed decisions when faced with similar challenges.

1. Sieving

Sieving is a widely used physical method for separating mixtures based on particle size.

In the case of steel ball bearings and marbles, sieving can be employed to separate them successfully.

The mixture is poured onto a sieve with appropriately sized openings.

As the mixture is agitated, the smaller marbles will pass through the sieve, while the larger steel ball bearings will remain on top.

This process can be repeated with different-sized sieves to further refine the separation.

Sieving

2. Magnetic Separation

Another effective method for separating steel ball bearings from marbles is magnetic separation.

Steel ball bearings are typically made of ferromagnetic materials, which means they can be attracted to magnets.

By placing a magnet near the mixture, the steel ball bearings will be attracted to it, allowing them to be easily separated from the marbles.

This method is particularly useful when the steel ball bearings are magnetic while the marbles are not.

3. Density-Based Separation

Density-based separation exploits the differences in density among the components of a mixture.

In the case of steel ball bearings and marbles, steel has a higher density compared to most types of marbles.

Utilizing this disparity, a physical method known as density-based separation can be applied.

The mixture is immersed in a liquid medium, such as water, and agitated gently.

Due to their higher density, the steel ball bearings will sink to the bottom, while the marbles will float. Careful extraction can then separate the two components effectively.

Density-Based Separation

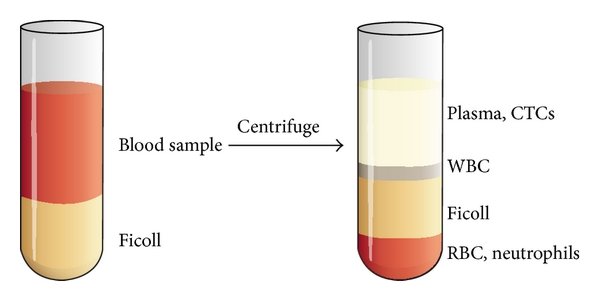

4. Centrifugation

Centrifugation is a powerful technique used to separate mixtures based on density and size.

In this method, the mixture is placed in a centrifuge and spun at high speeds.

The centrifugal force generated causes the denser and larger steel ball bearings to move towards the outer edge, while the lighter marbles remain closer to the center.

By carefully collecting the separated components at their respective positions, the mixture can be successfully separated.

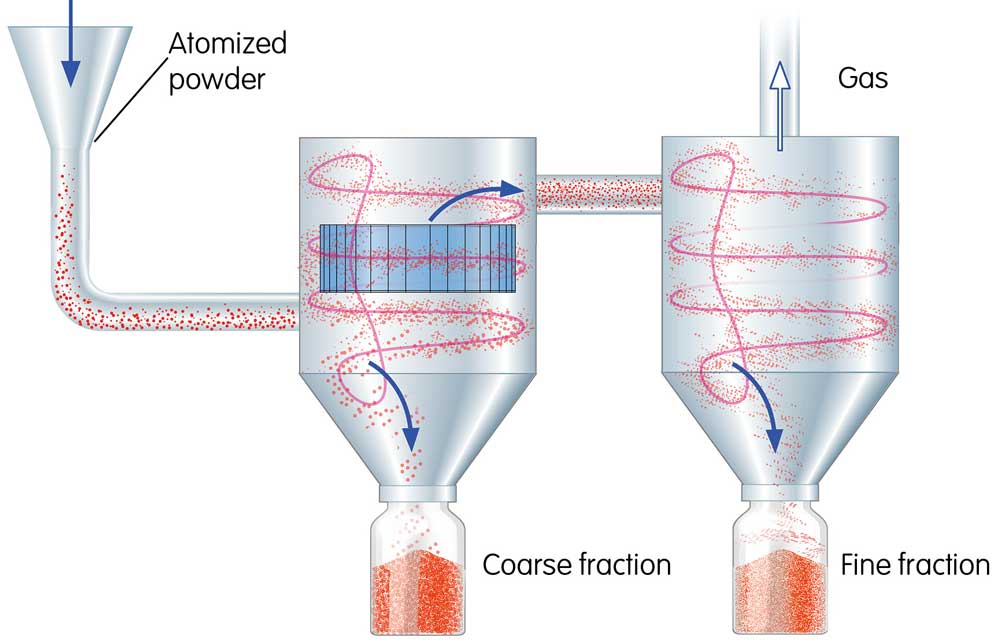

5. Air Classification

Air classification, also known as air separation or pneumatic separation, is a method used to separate particles based on their size and aerodynamic properties. In the case of steel ball bearings and marbles, this technique can be employed.

The mixture is introduced into an air stream, and the particles are subjected to differential drag forces based on their size and shape. The lighter marbles will be carried further by the air stream, while the heavier steel ball bearings will settle down, allowing for their separation.

Air Classifier AC series

When faced with the challenge of separating a mixture containing steel ball bearings and marbles, several physical methods can be employed effectively.

Sieving, magnetic separation, density-based separation, centrifugation, and air classification are all viable options depending on the specific properties of the components involved.

Understanding these methods provides professionals and enthusiasts with the knowledge to make informed decisions and achieve successful separations in various industrial and scientific applications.