The Production of Acetylene from Methane: A Comprehensive Overview

Acetylene, a highly versatile chemical compound, plays a crucial role in various industries, including manufacturing, metal fabrication, and chemical synthesis. One of the primary methods of producing acetylene is through the process of methane cracking, commonly known as "metan ra axetilen" in Vietnamese. In this article, we delve into the process of producing acetylene from methane, exploring its significance, applications, and the underlying chemical reactions involved.

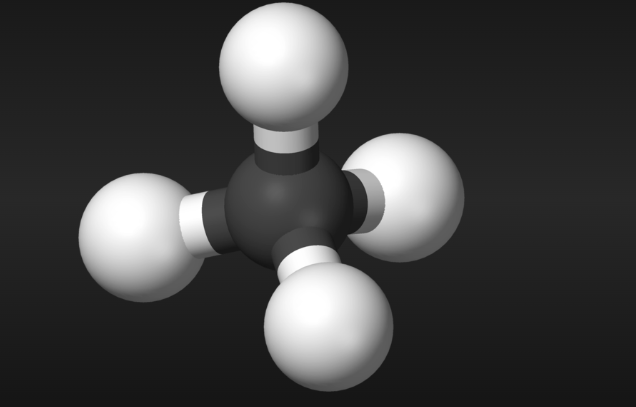

Methane - 3D ball

I. Understanding Acetylene and its Importance

Acetylene is a hydrocarbon compound with the chemical formula C2H2.

It is a highly reactive and flammable gas that has various applications across different industries.

Acetylene is commonly used in metal fabrication for welding, cutting, and brazing processes.

It is also utilized in the chemical industry for the synthesis of numerous organic compounds.

II. The Methane Cracking Process

Methane cracking, or the production of acetylene from methane, involves subjecting methane (CH4) to high temperatures in the presence of a catalyst.

The process breaks down the methane molecules, resulting in the formation of acetylene (C2H2) and hydrogen (H2) gases. The reaction can be represented as follows:

CH4 → C2H2 + 2H2

III. Chemical Reactions in Methane Cracking

In methane cracking, the carbon-hydrogen (C-H) bonds in methane are broken, leading to the formation of carbon-carbon (C-C) triple bonds in acetylene. The reaction requires a significant amount of energy due to the strength of the C-H bonds. The process is typically conducted at high temperatures ranging from 800 to 1200 degrees Celsius. The choice of catalysts, such as nickel or palladium, promotes the cracking reaction and enhances its efficiency.

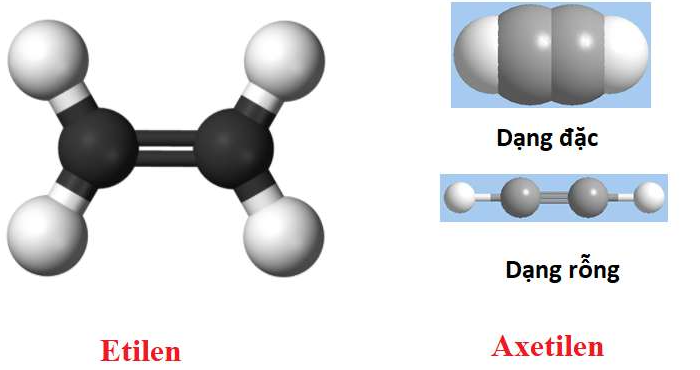

During the methane cracking process, byproducts and impurities may also be formed. These include ethylene (C2H4), propylene (C3H6), benzene (C6H6), and soot. Controlling reaction conditions, such as temperature, residence time, and catalyst selection, is crucial to minimize the formation of unwanted byproducts and ensure the production of high-quality acetylene.

IV. Industrial Methane Cracking Techniques

There are two primary techniques employed for methane cracking: thermal cracking and catalytic cracking.

1. Thermal Cracking Process: In thermal cracking, methane is heated to high temperatures without the presence of a catalyst. The heat causes the methane molecules to break apart, leading to the formation of acetylene and hydrogen gases. This process is energy-intensive and typically yields lower purity acetylene.

2. Catalytic Cracking Process: Catalytic cracking involves the use of a catalyst to enhance the cracking reaction. The catalyst lowers the activation energy required for the reaction, allowing for lower operating temperatures and improved efficiency. Catalytic cracking is the preferred method for commercial production of acetylene as it provides higher purity and better control over the reaction.

V. Safety Considerations in Acetylene Production

The production of acetylene involves handling a highly flammable gas. Proper safety measures must be implemented to ensure worker safety and prevent accidents. Acetylene is stored and transported in specialized cylinders filled with a porous material saturated with acetone. This prevents the gas from decomposing and minimizes the risk of explosion. Adequate ventilation, fire-resistant storage areas, and adherence to safety protocols are essential when working with acetylene.

VI. Environmental Impact and Sustainability

Acetylene production has environmental implications, primarily due to its association with fossil fuel usage and greenhouse gas emissions. The high temperatures required in the methane cracking process contribute to carbon dioxide (CO2) emissions. However, advancements in technology and the integration of renewable energy sources can help reduce the environmental impact of acetylene production. Exploring alternative methods such as bio-based production or utilizing renewable energy in the cracking process can contribute to sustainability.

VII. Advancements in Acetylene Production Technology

Ongoing research and development efforts aim to enhance the efficiency and sustainability of acetylene production. Innovations in catalyst design and reaction systems allow for improved control over the process, increased yield, and reduced energy consumption. Integrating renewable

Etilen and Axetilen

The production of acetylene from methane plays a crucial role in various industries. Understanding the process, chemical reactions, and safety considerations associated with acetylene production is vital for its successful and efficient manufacture. Additionally, embracing inclusion and promoting diversity within the industry ensures equal opportunities and a sustainable future. By continuously advancing technology, considering environmental impacts, and fostering a diverse and inclusive workforce, the acetylene production industry can thrive and contribute to a wide range of applications across various sectors.